Introduction of Twin Screw Pump

The twin-screw pump is a positive displacement pump with two intermeshing screws, efficiently transferring liquids with low pulsation. Widely used in various industries, it offers reliable and consistent fluid delivery, handling viscous and abrasive substances. Its robust design and versatility make it suitable for applications such as oil and gas, chemical processing, and marine transport, ensuring optimal performance and minimal maintenance requirements.

After years of R&D and improvement, SeFluid's STSP series twin screw pump has continuously improved its efficiency and quality. It has been used in many industrial fields that cannot be replaced by conventional centrifugal pumps and has been highly praised by users.

specification

Power

1.5-22 kw

Capacity

3-80 t/h

Speed

0-1480 rpm

Material

SS304, SS316

Download CatalogueHow a Twin Screw Pump Works

A twin screw pump is a positive displacement pump that uses two intermeshing screws to move fluid through the pump chamber. It is commonly used in various industries, including oil and gas, chemical processing, and food processing. Here's how a twin screw pump works:

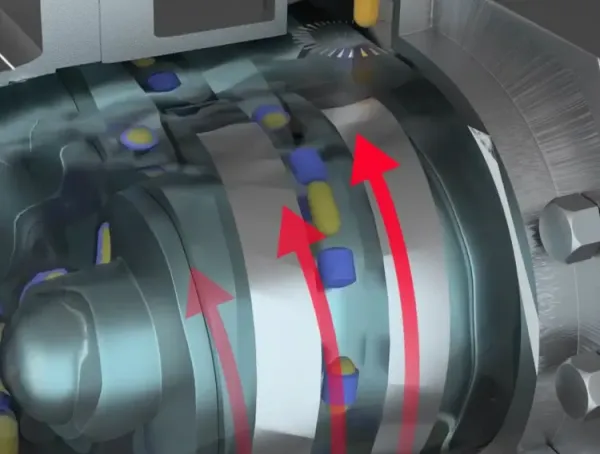

- Pump Chamber: The pump consists of a casing or chamber that houses two parallel screws. The screws have a specific profile with threads and intermeshing lobes.

- Suction Phase: Initially, the pump chamber is filled with fluid, and the screws rotate in opposite directions. As the screws rotate, the fluid is trapped between the threads and the lobes of the screws.

- Fluid Movement: As the screws rotate, the fluid is carried from the suction side to the discharge side of the pump chamber. The intermeshing of the screws creates sealed cavities that progressively move the fluid along the length of the screws.

- Sealing: The close tolerances between the screws and the pump chamber walls help in creating a tight seal, preventing the fluid from leaking backward or bypassing the screws. This makes the twin screw pump suitable for handling viscous fluids and liquids with high solids content.

- Discharge Phase: As the fluid moves towards the discharge side of the pump chamber, it gets compressed due to the decreasing volume between the screws' threads and lobes. This compression increases the pressure of the fluid, allowing it to be discharged through the pump's outlet.

- Efficiency: The design of the twin screws minimizes axial forces and provides a smooth and balanced flow, resulting in efficient and low-pulsation operation. The pump can handle different viscosities, ranging from thin liquids to highly viscous materials.

- Cooling and Lubrication: In some twin screw pump designs, a small portion of the pumped fluid is used to lubricate and cool the screws and bearings. This ensures the proper functioning and longevity of the pump.

Twin screw pumps are known for their reliability, versatility, and ability to handle challenging fluids. They are often preferred in applications where gentle handling of fluids, high efficiency, and consistent flow are required.

Advantages of Twin Screw Pump

Twin screw pumps offer several advantages over other types of pumps. Here are some of the key advantages of twin screw pumps:

Ability to Handle Viscous Fluids

Twin screw pumps are particularly well-suited for handling viscous fluids, including thick oils, slurries, and liquids with high solids content. The intermeshing screws create a tight seal, allowing the pump to efficiently move thick and sticky substances without clogging or shearing the product.

Smooth and Low-Pulsation Flow

Twin screw pumps provide a smooth and continuous flow of fluid, with minimal pulsation or pressure fluctuations. This is especially important in sensitive applications where a consistent flow rate is required to prevent product damage or maintain process stability.

Self-Priming Capability

Twin screw pumps are often self-priming, meaning they can evacuate air or gases from the pump chamber and create a vacuum to draw in the fluid. This eliminates the need for an external priming mechanism and makes the pump easier to start up.

High Efficiency

The design of twin screw pumps results in high volumetric efficiency, allowing them to deliver a greater volume of fluid per unit of power input. This efficiency is maintained across a wide range of viscosities, making twin screw pumps energy-efficient and cost-effective over the long term.

Gentle Handling of Shear-Sensitive Products

Twin screw pumps have a gentle pumping action that minimizes shear forces on the fluid. This is crucial for handling shear-sensitive products, such as certain chemicals, food products, and pharmaceuticals, where maintaining the integrity of the product is essential.

Versatility

Twin screw pumps are highly versatile and can handle a wide range of fluids, including liquids with varying viscosities, abrasive materials, corrosive substances, and even gases. They are commonly used in industries such as oil and gas, chemical processing, food processing, wastewater treatment, and marine applications.

Reliability and Durability

Twin screw pumps are known for their robust construction and reliable operation. They are designed to handle demanding conditions, including high pressures, high temperatures, and abrasive fluids. With proper maintenance, twin screw pumps can provide long service life and minimize downtime.

Features of SeFluid's Twin Screw Pump Series

SeFluid, a leading innovator in fluid handling solutions, is proud to introduce its state-of-the-art Twin Screw Pump Series. Designed with meticulous attention to detail and engineered for durability, our pumps offer superior performance across a wide range of applications where precise flow control and low shear are paramount. Below are the distinguishing features that set SeFluid's Twin Screw Pumps apart from the competition:

- Screw Head Technology: Each screw head in our pump series has undergone a specialized treatment process, which significantly reduces the potential for seizing between the screw head and the pump housing. This thoughtful design enhancement ensures a longer service life and minimizes maintenance needs.

- Mechanical Seal System: The mechanical seals on SeFluid's twin screw pumps are crafted using high-quality silicon carbide and hard alloy materials. Customers have the flexibility to choose between single and double mechanical seal options based on their specific application requirements. These robust seals ensure reliable containment and longevity.

- Robust Shafts: Our shafts are fabricated from specially treated alloy material, chosen for its exceptional resistance against compression forces and corrosion. This guarantees the shaft's integrity and contributes to the overall durability and operational efficiency of the pump.

- Sanitary Gearbox Construction: In adherence to stringent hygiene standards, the gearbox body of SeFluid's Twin Screw Pump Series is made from food-grade 304 stainless steel. This not only meets but exceeds industry expectations for cleanliness and long-lasting performance.

- Top-tier Bearings: To bolster the pump's reliability and lifespan, we have incorporated NSK bearings from Japan. Known for their superior quality, these bearings ensure smooth operation and reduce the need for frequent replacements or repairs.

- High-Temperature Resistant O-Rings: SeFluid utilizes O-rings manufactured from premium high-temperature-resistant materials. These O-rings can endure temperatures well above 200 degrees Celsius, ensuring consistent sealing even under the most demanding thermal conditions.

- Precision Helical Gears: The internal and external surfaces of the synchronous helical gears in our pumps are meticulously ground by advanced machinery. This precision engineering allows for seamless forward and reverse rotation capabilities, reducing noise levels and contributing to an exceptionally quiet operating environment.

SeFluid's Twin Screw Pump Series exemplifies our commitment to excellence, offering unparalleled functionality and durability. With innovative design features such as specialized screw heads, high-performance seals, corrosion-resistant shafts, sanitary gearboxes, top-quality NSK bearings, and heat-resistant O-rings, our pumps deliver dependable performance across various industries and applications. Invest in SeFluid's Twin Screw Pump Series today, and experience the future of fluid processing technology – designed for the long haul and built to exceed your highest expectations.

Applications of Twin Screw Pump

Twin screw pumps are versatile and can be used in various industries and applications. Here are some common applications of twin screw pumps:

- Oil and Gas Industry: Twin screw pumps are widely used in the oil and gas industry for pumping crude oil, refined products, and natural gas liquids (NGLs). They are suitable for handling a wide range of viscosities, from light hydrocarbons to heavy oils.

- Chemical Industry: Twin screw pumps are used in the chemical industry for transferring various liquids, including corrosive chemicals, solvents, resins, polymers, and adhesives. They offer gentle handling of shear-sensitive fluids and can handle high viscosities.

- Food and Beverage Industry: Twin screw pumps find applications in the food and beverage industry for handling products such as chocolate, syrups, sauces, dairy products, and beverages. They offer hygienic design options, making them suitable for sanitary applications.

- Pharmaceutical Industry: Twin screw pumps are used in the pharmaceutical industry for transferring viscous and shear-sensitive liquids, including pharmaceutical ingredients, creams, ointments, and lotions. They meet the stringent requirements for cleanliness and sterility.

- Marine and Offshore Applications: Twin screw pumps are employed in marine and offshore applications, including fuel transfer, ballast water handling, lubrication, and cargo pumping. They can handle high flow rates and provide reliable performance in challenging environments.

- Power Generation: Twin screw pumps are used in power plants for fuel oil transfer, lubrication, and cooling water circulation. They can handle a wide range of fluids, including heavy fuel oils, light oils, and water-glycol mixtures.

- Pulp and Paper Industry: Twin screw pumps find applications in the pulp and paper industry for pumping various fluids, including slurry, chemicals, coatings, and wastewater. They offer high efficiency and can handle abrasive fluids.

- Mining and Mineral Processing: Twin screw pumps can be used in mining and mineral processing applications for pumping slurry, tailings, and various chemicals used in the extraction and processing of minerals. They are capable of handling high solids content.

- Wastewater Treatment: Twin screw pumps are employed in wastewater treatment plants for pumping sludge, grit, and other wastewater streams. They offer robust construction and can handle challenging fluids with solids.

- General Industrial Applications: Twin screw pumps have numerous applications in general industrial processes for transferring fluids, including lubricants, hydraulic oils, coolants, and process fluids.

These are just a few examples of the many applications of twin screw pumps. Their ability to handle a wide range of fluids, including viscous and shear-sensitive liquids, makes them a popular choice in various industries.

Request for Quotation

Talk to us now !

We strongly recommend that you either click or scan the QR code below to talk directly with our sales engineers so that we can help you find the most suitable products for your application needs.

Telegram

Messenger

Viber

Skype

related

news

contact

No 10, Jinhai Rd, Hefei, China 201400

Phone: +86 156 6910 1862

Fax: +86 551 5843 6163

sales@sefluid.com

follow us