Introduction of Colloid Mill

The colloid mill is a kind of machine for fine milling of fluid and semi-fluid materials. It has excellent superfine pulverization, dispersion, emulsification, homogenization and mixing. With this device, particle size of raw material can reach 2-60 microns after processing, and the homogeneity can reach more than 95%. Therefore, it is an ideal equipment for ultra-micro processing.

Compared with pressure homogenizers, firstly colloid mill is a centrifugal equipment. Secondly, it has the advantage of simple structure and easy maintenance. In addition, it is suitable for high viscosity materials and materials with large particles. The machine combines the various properties of ball mills, three-roll mills, mixers and other machinery. Meanwhile its efficiency is several times that of the above-mentioned machinery.

SeFluid has years of experience in the production of colloid mills and are capable of manufacturing various specifications and types of colloid mills to meet different customer needs. Over the years, our products have been exported to all over the world, and with excellent quality and good service, they have received high praise from our customers.

specification

Motor Power

1.1-22 kw

Capacity

0.01-10 t/h

Fineness

2-40 μm

Material

SS304, SS316

Download CataloguePrinciple of Colloid Mill

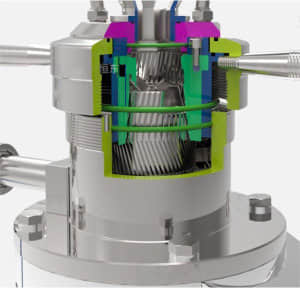

https://youtu.be/9QbO7_gexHMOn SeFluid's colloid mill series, a motor drives a rotating tooth (or rotor) through a belt drive. And, the rotor rotates at high speed against a matching stationary stator. The processed material is pressurized by its own weight or by external pressure (which can be generated by a pump). As a result, a downward spiral impact force occurs. The material flows through the gap between the fixed and rotating teeth (adjustable gap).

Meanwhile the material is subjected to strong shear forces, friction, high frequency vibrations and high speed vortices. As a result, it is effectively emulsified, dispersed, homogenized and crushed. Ultimately, the effect of ultra-fine crushing and emulsification of materials is achieved.

Except for the motor, all parts in contact with the processed material are made of high strength stainless steel. Most importantly, the key grinding components, both rotator and stator are reinforced. Therefore the parts have good corrosion and abrasion resistance. So, processed material is pollution-free and hygienically pure.

Features of SeFluid's Colloid Mill Series

Applications of Colloid Mill

The colloid mill is a versatile machine that is used in a wide range of industries to process materials such as emulsions, suspensions, and other similar products. Here are some of the common applications of the colloid mill:

Food Industry

It is widely used in the food industry to produce emulsions, such as mayonnaise, salad dressings, and sauces. It is also used to produce peanut butter, almond butter, and other nut butters. In addition, the colloid mill is used in the production of dairy products such as cheese, yogurt and cream.

Pharmaceutical Industry

The machines are used in the pharmaceutical industry to produce suspensions, gels, and creams. They are also used to produce ointments, lotions, and other topical products. The colloid mill is ideal for producing pharmaceutical products because it can produce small particle sizes and a uniform particle size distribution.

Chemical Industry

Colloid mills are used in the chemical industry to produce pigments, paints, and other similar products. It is also used to produce adhesives, lubricants, and other industrial products.

Cosmetic industry

This type of mills is ideal for the cosmetic industry to produce creams, lotions, and other similar products. It is also used to produce makeup products such as lipstick, mascara, and foundation. They are ideal for producing cosmetic products because it can produce small particle sizes and a uniform particle size distribution.

Biotech industry

The colloid mill is used in the biotech industry to produce cell suspensions, protein solutions, and other similar products. It is also used to produce vaccines and other biopharmaceutical products. The colloid mill is ideal for producing biotech products because it can produce small particle sizes and a uniform particle size distribution.

Petroleum Industry

It is used in the petroleum industry to produce drilling muds and other similar products. It is also used to produce lubricants and other industrial products. The machines are ideal for producing petroleum products because they can handle a wide range of materials and produce small particle sizes.

In addition, colloid mill is used in many other industries such as paper and pulp, textile, and mining. It can also be used in research and development laboratories to produce small batches of products for analysis.

Request for Quotation

RELATED

NEWS

CONTACT

No 10, Jinhai Rd, Hefei, China 201400

Phone: +86 156 6910 1862

Fax: +86 551 5843 6163

sales@sefluid.com

FOLLOW US

https://www.sefluid.com/products/adjustable-superfine-colloid-mill/?feed_id=244&_unique_id=6563c7b8d6943

https://www.sefluid.com/products/adjustable-superfine-colloid-mill/?feed_id=244&_unique_id=6563c7b8d6943